Rolex Dial Restoration: Preserving Legacy Through Craftsmanship

Throughout my career, I’ve encountered many fascinating aspects of horology, but one phenomenon stands out - some watches carry deep sentimental value for their owners. A timepiece worn by a father or grandfather can become a cherished heirloom, far beyond its monetary worth. In fact, I've worked with siblings collaborating on the restoration of a special Rolex passed down from their grandfather.

In some cases, these watches only require a movement overhaul and some polishing. But other times, they suffer from extensive water damage, resulting in rust not just within the movement, but also on the dial surface.

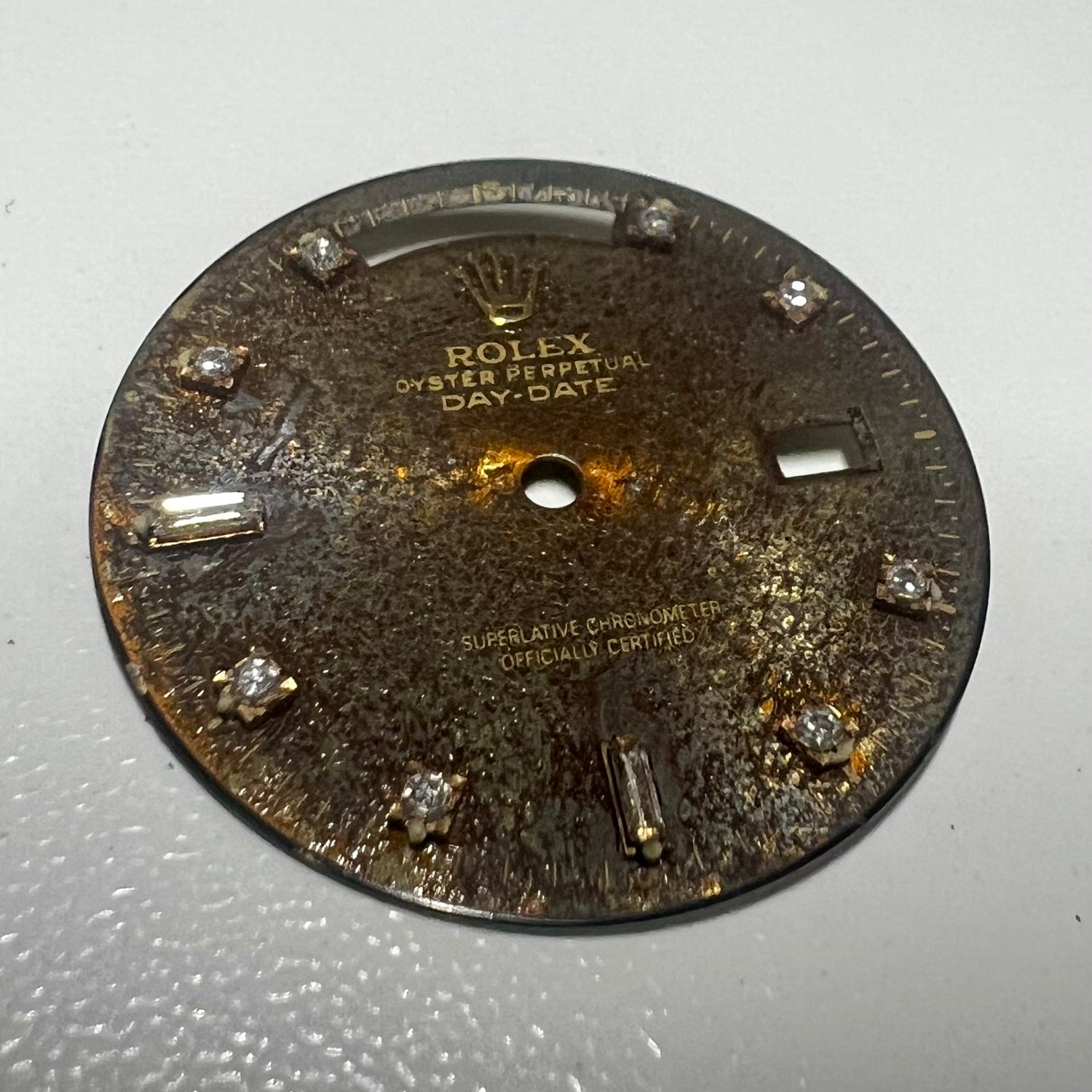

Recently, I had the opportunity to work on a Rolex Day-Date 18038 dial that had the most rust I’ve ever seen.The dial was completely covered in corrosion.

Despite the damage, the customer wanted to preserve as much of the original appearance and parts as possible. Anyone who has tried sourcing an original factory Rolex dial knows how expensive and rare they are, especially those with diamonds. Most of the dials available on the secondary market lack these features. As expected, we were unable to source a factory champagne diamond dial for this model - especially one with the specific diamond mounts it originally had. Unfortunately, that left us with only one option: restoring the original dial.

After explaining all of this to my customer, he made the heartfelt decision to restore his father's original dial.

This project was done in several steps:

STEP 1:

As part of the restoration process, we begin by removing all the original diamond hour markers and the crown logo. These markers are made of gold, and with ultrasonic cleaning, the rust typically comes off quite cleanly - leaving the diamonds and their mounts looking almost brand new.

However, the initial cleaning didn't remove all the rust off the dial and revealed significant damage to the surface - damage that couldn’t be chemically removed.

Normally, I would stop at this point and opt to have the dial resurfaced. But knowing how refined and unique the original Rolex sunburst texture is - far superior to anything we could replicate - I decided to make a second attempt at chemical cleaning. This revealed even deeper pitting and corrosion caused by rust.

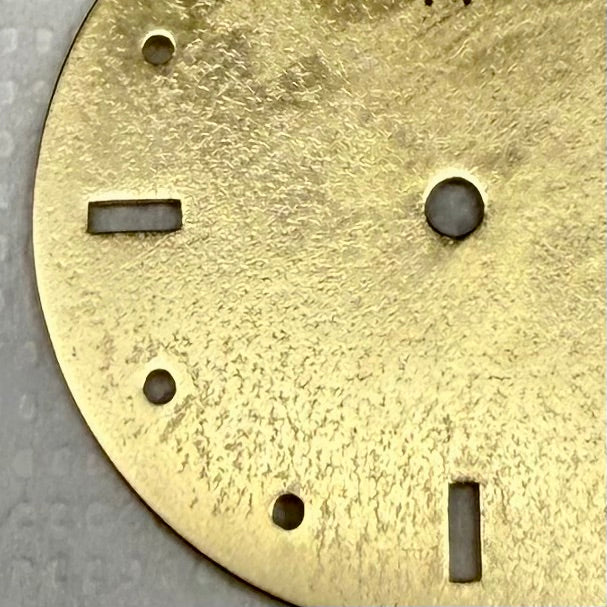

At that stage, I had to bring in another specialist to help resurface the entire dial and recreate the sunburst texture.

STEP 2:

Once the texturing was complete, we moved on to gold plating and applying a clear coat. The results were good, though not perfect. We had to make several attempts to get it right. The sunburst lines became more visible, but not as crisp as I had hoped for. The original Rolex sunburst finish is much more refined. What we achieved was simpler - but only when compared to a modern Rolex dial. This was an '80s watch, and the original finish was quite similar to what we recreated. In fact, we were likely using the same techniques and methods Rolex used 30–40 years ago.

STEP 3:

The next stage was reprinting the dial text.The technology for this process hasn’t changed in over a century - we still use pad printing, just as the specialists before us did. I’ve noticed that many aftermarket budget dials today use screen printing instead. While it’s a more affordable option, especially for those seeking the cheapest possible dial, the results are noticeably inferior. Screen-printed text appears flat and lacks the definition and depth of authentic Rolex printing.The machine shown in the picture isn’t mine - it’s a discontinued Bergeon dial printing machine. My own machine is quite similar, though it was made in Germany in the 1950s. I’ve always admired Swiss-made Bergeon tools for their precision and craftsmanship.

STEP 4:

The final step is reinstalling the original factory diamond hour markers, along with the iconic crown logo at the 12 o’clock position.